Our Technology

Get to know the different adphos technologies!

Harnessing the Power of the Radiation Spectrum

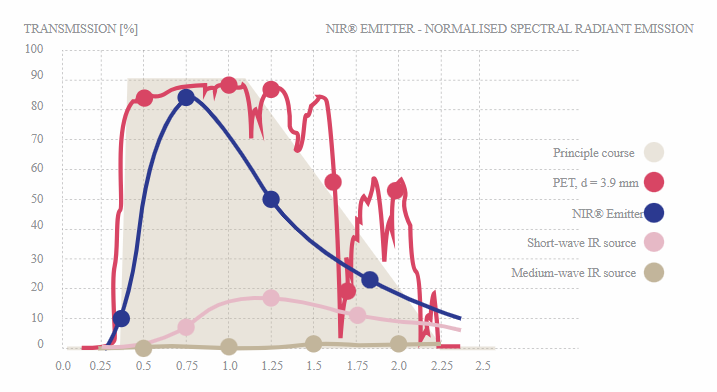

Thermal and drying processes rely on the electromagnetic spectrum, spanning from UV light through visible light to Near-InfraRed (NIR) and beyond.

NIR, positioned just above visible light, offers the highest energy density and optimal physical properties for industrial applications. With proprietary aNIR® and aLITE® technologies, we unlock the full potential of this spectrum, enabling rapid, targeted, and efficient thermal processing.

Operating within the 800 nm to 1,200 nm wavelength range, aNIR® and aLITE® deliver:

- Maximum energy density in the smallest areas

- Minimal impact on substrates and surrounding environments

- Faster, more efficient industrial production

Advanced Thermal Processing with aNIR® and aLITE®

aNIR® and aLITE® technologies are game-changers for a wide range of thermal processes, including:

- Drying – Fast removal of water and solvents from inks, paints, and coatings

- Curing – Efficient hardening of powder coats, primers, and topcoats on various substrates

- Sintering – Precision sintering of conductive and resistive inks for Printed Electronics (PE) applications

- Annealing – Ideal for processing brake pads, metals, and other high-performance materials

With unparalleled speed and energy efficiency, adphosNIR® enables higher throughput, lower operating costs, and greater process control across multiple industries.

adphosNIR®– Precision and Efficiency

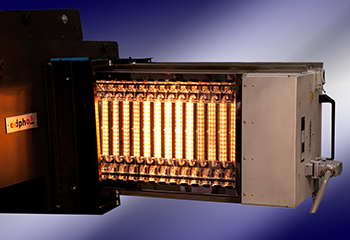

adphos aNIR® technology redefines thermal processing by combining Near-Infrared (NIR) light energy, advanced energy management, integrated hot air, and efficient moisture extraction into a high-speed, energy-efficient solution.

Unlike conventional heating methods that first warm the substrate, adphos technology works similar to a microwave, directly exciting water and solvent molecules for instant, precise, and uniform thermal processing. Unlike microwaves however, adphos technology does not generate microwaves or any other harmful radiation.

Why Choose aNIR®

- Ultra-Fast Photonic Processing – Accelerates drying, curing, sintering, and annealing processes

- Maximum Energy Efficiency – Reduces heat loss and operating costs

- Precise Temperature Control – Ensures optimal performance across diverse materials

- Compact & Scalable – Easily integrates into existing production lines

- Fully Electrothermal – enables processes completely CO2 emission free

With the highest energy density in the NIR spectrum, aNIR® delivers faster throughput, lower energy consumption, and superior results, making it the ultimate solution for demanding industrial applications.

aLITE® – The Next Generation Precision for Demanding Applications

Engineered for the most challenging thermal processing environments, aLITE® technology takes performance, precision, and control to the next level.

While building upon the proven foundation of aNIR® technology, aLITE® introduces unparalleled adaptability and efficiency, making it ideal for high-performance drying, curing, and heating applications, especially for thermal sensitive products.

Key Advantages of aLITE® Technology:

-

Thermal Optimization – Both passive and active heating elements offer precise, independent temperature control, ensuring uniform heat distribution and optimized energy efficiency

-

Precision Airflow Control – Input and exhaust air volume and velocity are fully adjustable, allowing for precise process tuning based on material and application requirements

-

Enhanced Process Flexibility – The ability to fine-tune airflow and temperature completely independent from each other delivers superior results for delicate, heat-sensitive, or high-speed production applications, even under explosive conditions

-

Fully Electrothermal – enables processes completely CO2 emission free

With aLITE®, manufacturers can achieve greater consistency, reduced energy consumption, and improved production speeds, making it the ultimate solution for demanding thermal processing needs across industries.